IIT Guwahati’s new tech to convert methane, CO2 to biofuel using bacteria

Researchers at the Indian Institute of Technology (IIT) Guwahati have developed an advanced biological method to convert methane and carbon dioxide (CO2) into cleaner biofuels using methanotrophic bacteria.

Guwahati, Dec 9 (IANS) Researchers at the Indian Institute of Technology (IIT) Guwahati have developed an advanced biological method to convert methane and carbon dioxide (CO2) into cleaner biofuels using methanotrophic bacteria.

The innovative approach, which addresses two pressing global challenges: the harmful environmental impact of greenhouse gases and the depletion of fossil fuel reserves, represents a significant leap toward sustainable energy solutions and climate change mitigation.

Methane, a greenhouse gas that is 27-30 times more potent than CO2, is a significant contributor to global warming. While turning methane and CO2 into liquid fuels can reduce emissions and provide renewable energy, existing chemical methods are energy-intensive, expensive, and produce toxic by-products, limiting their scalability.

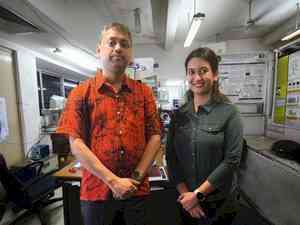

The team from IIT Guwahati developed a fully biological process that uses Methylosinus trichosporium -- a type of methanotrophic bacteria -- to convert methane and CO2 into bio-methanol under mild operating conditions.

Unlike traditional chemical methods, this process eliminates the need for expensive catalysts, avoids toxic by-products, and operates in a more energy-efficient manner.

“This research is a breakthrough as it demonstrates that bio-methanol, derived from bacteria feeding on methane and carbon dioxide, can be a viable alternative to fossil fuels,” said Prof. Debasish Das, Dept. of Biosciences and Bioengineering, IIT Guwahati.

“Unlike conventional biofuels that rely on crops and create competition with food production, our method uses greenhouse gases, avoiding the ‘food vs. fuel’ issue. It is an environmentally and economically viable solution, utilising inexpensive resources while contributing to emissions reduction,” Das added.

The innovative two-stage process involves capturing methane to generate bacteria-based biomass and utilising the biomass to convert carbon dioxide into methanol.

The team further optimised the process using advanced engineering techniques to improve gas solubility, significantly enhancing methanol yields.

The bio-methanol produced was blended with diesel (5-20 per cent ratios) and tested in a four-stroke diesel engine. The results described in the journal Fuel, include up to 87 per cent reduction in carbon monoxide, hydrocarbons, hydrogen sulphide, and smoke emissions.

Diesel-methanol blends also outperformed pure diesel in fuel consumption, energy efficiency, and engine performance, while maintaining similar mechanical efficiency.

The process offers immense potential to decarbonise critical industries, including oil and gas, refineries, and chemical manufacturing, paving the way for a more sustainable future, the researchers said.

IANS

IANS