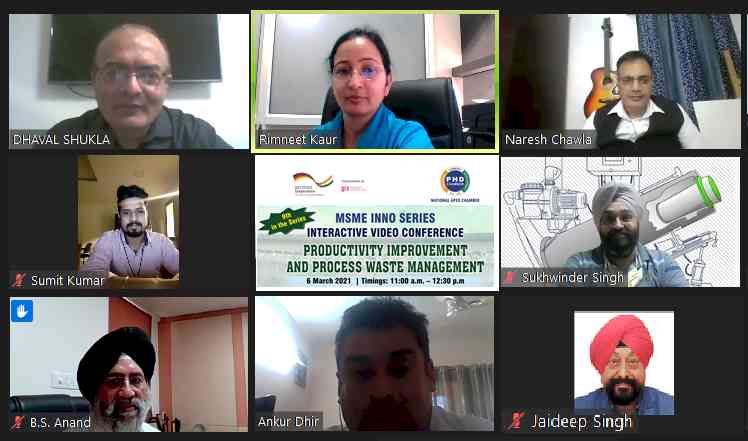

Innovation the key to success: Experts at PHDCCI video conference

The Video Conference was held on Productivity Improvement through Process Waste Reduction

New Delhi: PHD Chamber of Commerce and Industry (PHDCCI) in association with GIZ organized a Video Conference on Productivity Improvement through Process Waste Reduction with the objective to create awareness about the principles of lean manufacturing and ZED model in manufacturing.

Mr. Naresh Chawla, Senior Consultant, Kaizen Institute India made a detailed presentation on improving productivity and processing waste management. He said that productivity is the prime factor determining the competitiveness of a company. Productivity depends on efficiency, effectiveness and adaptability. He pointed out that during covid-19 pandemic, only those companies survived who modified their operations according to the changed circumstances.

Mr. Chawla shared that for entrepreneurs productivity and resource utilization have a cap as they cannot go beyond 100 per cent but methodology has unlimited scope as technology can be leveraged to improve productivity infinitely. He added that return on money invested is a measure of efficiency. He explained that efficiency implies how fast an entity is able to rotate its assets.

Mr. Chawla underlined that innovation is key to success for businesses as it leads to enhanced sales and better profit margin. Therefore, new product, new method of production, new source of raw material, creation of monopoly, breaking up monopoly and exploring new markets are extremely important for businesses.

Highlighting the importance of elimination of wastage, Mr. Chawla said that in addition to preventing material wastage, focus should be to avoid wastage of time and manpower. He said that activities which consume time and resource but do not add value are categorized as non-value adding and should be avoided to increase profitability. He explained the 8 wastes with acronym DOWNTIME representing Defects, Overproduction, Waiting, Non-value added processing, Transportation, Inventory excess, Motion waste and Employee waste

Mr. Ankur Dhir, Principal Consultant & Trainer Quality Solutions, Chandigarh also made a presentation to explain the cost reduction techniques through material flow cost accounting (MFCA) and Zero Effect and Zero Defect (ZED) Model.

Mr. Dhir mentioned that material flow cost accounting (MFCA) is a management tool that assists organizations in better understanding the potential environmental and financial consequences of their material and energy practices and seeks to improve them via changes in those practices.

Speaking about the ZED Certification Scheme, Mr. Dhir explained that this is an extensive drive of the Government of India for inculcating Zero Defect & Zero Effect practices in manufacturing processes to ensure continuous improvement for enhancing global competitiveness of MSMEs in the country. The Scheme includes assessment of business processes, rating and handholding of MSMEs to optimize their production with intervention of experts.

He explained that for ZED certification, the MSMEs are assessed on various parameters including production management, quality management, environment management, energy managements, intellectual property management and safety management etc. Based on the existing systems and processes of manufacturing, a company is categorised into 5 different levels of maturity starting from learners, beginner, organized, achiever and world class.

The MSMEs are evaluated on various parameters under each model and depending on the score are rated as Bronze, Silver, Gold, Diamond and Platinum where bronze is the lowest rating with score ranging from 2.2 to 2.5 and Platinum is the highest rating with score above 4.0.

MSMEs enrolled in MSME INNO programme participated and benefited from the programme.

cityairnews

cityairnews