RCF Kapurthala manufactures second rake of coaches with added features for Udhampur-Baramulla rail link

Rail Coach Factory Kapurthala has produced the second rake of rail coaches specially manufactured for the newly constructed Udhampur-Baramulla rail link. This 23-coach rake includes 14 AC three tier, 5 AC two tier, 1 AC first class, 1 AC hot buffet car and 2 power car coaches. For the first time, automatic sliding doors have been fitted in these coaches, which is the main feature of these coaches. For the Udhampur-Srinagar-Baramulla rail route, four rakes of 88 coaches are being built in RCF besides seven spares coaches.

Kapurthala, June 6, 2024: Rail Coach Factory Kapurthala has produced the second rake of rail coaches specially manufactured for the newly constructed Udhampur-Baramulla rail link. This 23-coach rake includes 14 AC three tier, 5 AC two tier, 1 AC first class, 1 AC hot buffet car and 2 power car coaches. For the first time, automatic sliding doors have been fitted in these coaches, which is the main feature of these coaches. For the Udhampur-Srinagar-Baramulla rail route, four rakes of 88 coaches are being built in RCF besides seven spares coaches.

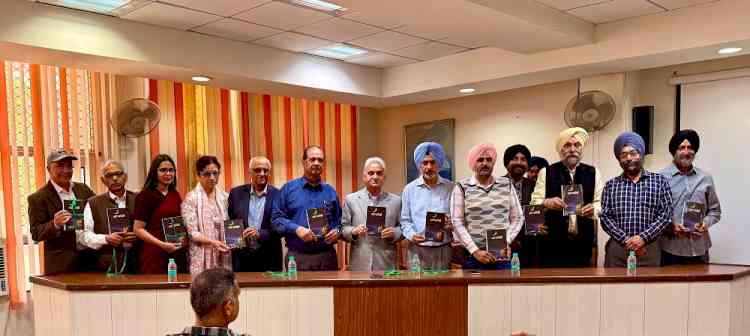

This newly manufactured rake was today inspected by Manjul Mathur, GM, Rail Coach Factory before final roll out. Arun Kumar Jain, PCME and other HODs were also present on the occasion . During the inspection, Mathur took a close look at the mechanical and electrical equipments that have been installed to run these coaches smoothly in extreme cold. After the inspection Mathur expressed his satisfaction over the manufacturing of these coaches and appreciated all the employees and officers who have contributed immensely from designing to manufacturing in such a short period of time.

Mathur thoroughly inspected the mechanical and electrical equipment installed in this newly built rake to provide comfortable travel to passengers. These arrangements include enhanced heating capacity and water heating system with modifications in Roof Mounted Package Unit (RMPU) and under-slung water pipelines and tanks. The RMPUs now have an increased heating load of 7.5 kW instead of 6 kW, and each unit is of 7 tonnes. Thermostats control on/off based on minimum and maximum temperature setting. Double-walled under-slung water tanks made of composite material with suitable thermal insulation have been used. Provision of heating cable arrangement has been made to ensure flow of water in the pipes during extreme cold.

The coaches are equipped with other unique features such as a slim switch board cabinet on the compartment door, CCTV, fire alarm, passenger information system, passenger announcement system besides LED destination boards.

Rajat Kumar

Rajat Kumar